Title: Special Requirements for Cooling Fans in the Aerospace Industry

The aerospace industry is a highly specialized field that demands nothing but the best in terms of technology, performance, and safety. With the rapid advancements in aviation technology, the demand for cooling fans in aerospace applications has increased significantly. These cooling fans are not just any ordinary fans; they need to meet stringent requirements to ensure the optimal performance of aerospace systems. In this article, we will discuss the special requirements for cooling fans in the aerospace industry and the challenges faced by manufacturers in meeting these requirements.

1. High Temperature Resistance

One of the most crucial requirements for cooling fans in the aerospace industry is their ability to operate efficiently at high temperatures. Aerospace systems, especially jet engines, generate a significant amount of heat during operation. The cooling fans are responsible for dissipating this heat to maintain the engine's temperature within acceptable limits. Therefore, they must be made of materials that can withstand high temperatures and remain durable and functional. Common materials used in the production of high-temperature resistant cooling fans include titanium, Inconel, and ceramic materials.

2. High-Speed Operation

Aerospace cooling fans are required to operate at very high speeds to generate the necessary airflow for cooling. These high speeds can lead to increased wear and tear on the fan's components, which can impact their performance and lifespan. To overcome this challenge, manufacturers use advanced aerodynamic designs and precision manufacturing techniques to ensure that the fans can operate at high speeds without compromising on their efficiency and durability.

3. Low Weight and Compact Design

The aerospace industry is constantly looking for ways to reduce the weight of aircraft and improve their fuel efficiency. Cooling fans play a significant role in this aspect as they contribute to the overall weight of the aircraft. Therefore, it is essential for cooling fans to be lightweight without compromising on their performance. Manufacturers achieve this by using lightweight materials and innovative design techniques to reduce the fan's weight while maintaining its structural integrity.

4. High Efficiency

Cooling fans in the aerospace industry must be highly efficient to ensure optimal performance of the systems they are cooling. Efficiency is determined by the fan's ability to move air at a low power consumption. Manufacturers achieve high efficiency by using advanced aerodynamic designs, optimized blade profiles, and high-quality materials in the production of cooling fans.

5. High Reliability and Long Lifespan

Aerospace cooling fans are expected to perform consistently and reliably in harsh environments. They must be able to withstand extreme temperatures, high pressures, and high speeds without fail. Manufacturers achieve high reliability and long lifespan by using high-quality materials, precision manufacturing techniques, and advanced quality control measures during the production process.

6. Environmental and Space Considerations

Cooling fans used in aerospace applications need to meet specific environmental and space constraints. For instance, they should be able to function effectively in the presence of dust, humidity, and other environmental factors that may affect their performance. Additionally, space-based applications may require cooling fans that can operate in a vacuum environment, which poses unique challenges for manufacturers.

7. Integration with Other Systems

Cooling fans in the aerospace industry need to be seamlessly integrated with other systems such as engines, avionics, and sensors. This requires close collaboration between various stakeholders, including designers, engineers, and manufacturers, to ensure that the cooling fans are compatible with other components and systems.

In conclusion, the aerospace industry demands a high level of expertise and precision from manufacturers in the production of cooling fans. Meeting the special requirements for these fans is a challenging task, but it is essential to ensure the optimal performance of aerospace systems. With advancements in technology and materials, manufacturers are constantly pushing the boundaries to meet these stringent requirements and provide efficient and reliable cooling solutions for the aerospace industry.

Title: The Importance of High-Efficiency Cooling Fans in Server Rooms Introduction Server rooms are an integral part of modern-day businesses, housing crucial data and applications that drive operations. The equipment within these rooms, such as servers, storage units, and networking devices, generate significant heat due to their constant use. This heat can lead to overheating, causing critical failures and affecting the overall performance of the devices. Therefore, it is crucial to maintain a suitabl...

Title: The Influence of Blade Design of Cooling Fan on Airflow and Air Volume Introduction: The cooling fan is an essential component in many industrial and domestic applications, such as air conditioning, refrigeration, and computer systems. The primary function of a cooling fan is to circulate air and maintain the desired temperature in the system. The blade design of the cooling fan plays a crucial role in determining its efficiency and performance. In this article, we will discuss the influence of ...

Title: Stability Requirements for Cooling Fans in Medical Equipment In the realm of medical equipment, stability is crucial. It ensures optimal performance, prevents any malfunctions, and ultimately safeguards patient lives. One of the key components that contribute to stability is the cooling fan. These fans are responsible for keeping the equipment at optimal temperatures, preventing overheating and ensuring smooth operation. As such, it's important to understand the stability requirements for cooling ...

The choice of cooling fan material can greatly affect its thermal performance. Common cooling fan materials include plastic, metal, alloy, ceramic and nanocomposite. Cooling fans made of different materials differ in thermal performance, durability, weight and cost.First of all, cooling fans made of plastic have the advantage of low production cost, but they are less tough and vulnerable to damage, so they may have problems when used in high-temperature environments. Cooling fans made of metals and alloys...

Centrifugal fans are an air-powered mechanical device widely used in a variety of industrial facilities. The following is a common application method, which enables centrifugal fans to realize automation control, improve work efficiency and reduce the risk of human misoperation.First of all, the automation control system of centrifugal fans can be realized through remote monitoring and commanding, on-site monitoring and control, data acquisition and detection. Through these ways, the running status of the...

Cooling fans are a widely used device in many production areas to help reduce the heat generated by machinery and equipment and to dissipate heat. For personal computers and automobiles, cooling fans are indispensable. In this article, we will explain how cooling fans work and why they are critical to the safety and performance of electrical equipment.Cooling fans work by moving air to remove the heat generated by the equipment. As the fan rotates, it creates a stream of air that removes heat from the equ...

Title: The Importance of High-Efficiency Cooling Fans in Server Rooms Introduction Server rooms are an integral part of modern-day businesses, housing crucial data and applications that drive operations. The equipment within these rooms, such as servers, storage units, and networking devices, generate significant heat due to their constant use. This heat can lead to overheating, causing critical failures and affecting the overall performance of the devices. Therefore, it is crucial to maintain a suitabl...

Cooling fan noise control methods can be divided into the following aspects:1. Fan design optimization: choose the right type of fan blade, such as large-size, low-speed fans. Compared with small-sized, high-rpm fans, these types of fans are not only quieter, but also more efficient.2. Reduce the effect of fan imbalance: fan imbalance can lead to strong vibration and noise, and can be reduced by using high-quality fan materials and superb processing technology.3. Adopt noise-reducing cover: Noise-reducing...

Explosion-proof axial fans

Notebook Cooling Bracket Fan

Single Impeller High Pressure Blowers

Motor external axial fans

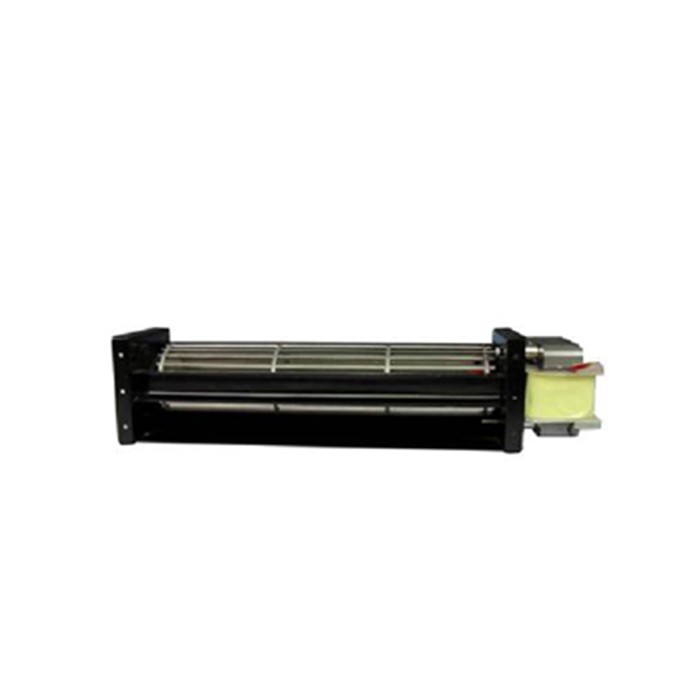

Roller Ball Crossflow Fans

Air Suspension Blowers

High-efficiency cooling cross-flow fans

Axial Exhaust Fans

AC Fan Power

Waterproof DC Fans

DC Fan Motors

Air pump centrifugal fans